Hayward, Pentair, Jandy

There are many different types of swimming pool pumps. Features can vary by type and by brand. This guide is designed to explain many of the common features as well as common problems you may encounter with your swimming pool pumps. This guide uses the installation, owners, and user manuals for the Pentair Whisperflow pumps as a reference. While much of the information is from the Pentair user manuals, this guide will help with all brands and types of swimming pool pumps. The problems, causes, and resolutions that apply to Pentair brand pumps also apply to Hayward and Jandy as well as other not so common brands. Use the following navigation to find the answer to your swimming pool pump questions, troubleshooting and parts.

- Different types of swimming pool pumps

- How does a pool pump work?

- Determine pump runtime for single-speed pool pump.

- Determine RPM, GPM, and runtime for a variable speed pool pump

- Swimming pool pump components

- Common pool maintenance items

- How to clean a pump strainer basket

- How to prime a swimming pool pump

- Swimming pool pump troubleshooting

- Low water pressure or low flow issues with your pool pump

- Suction leaks

- Lost prime

- Low voltage

- Clogged pipe or strainer

- Clogged filter

- Clogged impeller

- No water is coming from the pump

- Reduced pump capacity or head pressure

- Motor thermal overload issues

- No power at the pump

- Blow fuse or circuit breaker

- Burnt out motor

- The pump running too slowly

- Swimming pool pump water leak repair

- How to fix pool pump cavitation

What are the different types of swimming pool pumps?

Pool pumps are broken down into three basic categories. Single speed, dual speed, or variable speed.

Single-speed pool pumps

This type of pump runs at whatever RPM it is set for by the manufacturer. With a single-speed pump, the only control the user has is how often the pump comes on and for how long.

Dual-speed pool pumps

A dual-speed pump allows the user to choose usually between high flow and low flow rates. This is good if you want to continually run your pump at low speed and then occasionally run it at high speed to run a suction side vacuum or other feature.

Variable-speed pool pumps

Most modern pumps are now variable speed. For these pumps you can set any RPM or GPM rate you would like based on the conditions. If you want to just circulate the water slowly you can run the pump at a low speed such as 1000-1500 RPM. If you want to run a heater or salt cell you may need to run the pump at 2000-2800 RPM to get the proper flow rate. If you are trying to run in floor cleaning or a dedicated suction side vacuum you may need to run the pump at its maximum RPM which is usually around 3400 RPM. The nice thing about a variable speed pool pump is that when you need the higher power, you just adjust the RPM up, and for the majority of the time you can run on low speed saving a tremendous amount of power usage and money.

How does a pool pump work?

To effectively circulate your swimming pool water, you have a pump installed that spins an impeller at a certain rpm. This impeller sucks water from one of several locations in your pool. It moves the water through a pump filter basket and sends it to the pool filter. It is then “returned” to the pool via the return plumbing.

The suction side of the pool pump

Water can be pulled from your swimming pool by your pump from one or a combination of suction side locations. The usual locations are the main drain, skimmer, dedicated vacuum port, spa drain, or feature suction port.

Where the water is pulled from will be controlled by a valve or series of valves. These valves may be manual or automatic electric valves. Some valves may allow suction from more than one source at a time.

The whole point of the swimming pool pump is to circulate and filter your pool water. This guide is designed to explain how your pool pump works, what parts it is comprised of, and how to troubleshoot basic issues.

Return side of the pool pump

The “returns” are where the water goes back to the pool. Usually after being sucked from the pool from the suction side, water will travel through the pump, through the filters, through check valves, heaters, salt cells, etc, and eventually arrive at the returns. This can be split to return to the pool, spa, water features, or elsewhere to get back into the pool. The water that comes from the return side of the pump should be filtered, and cleaned as it enters the pool.

How to determine pool pump runtime when using a single-speed pump

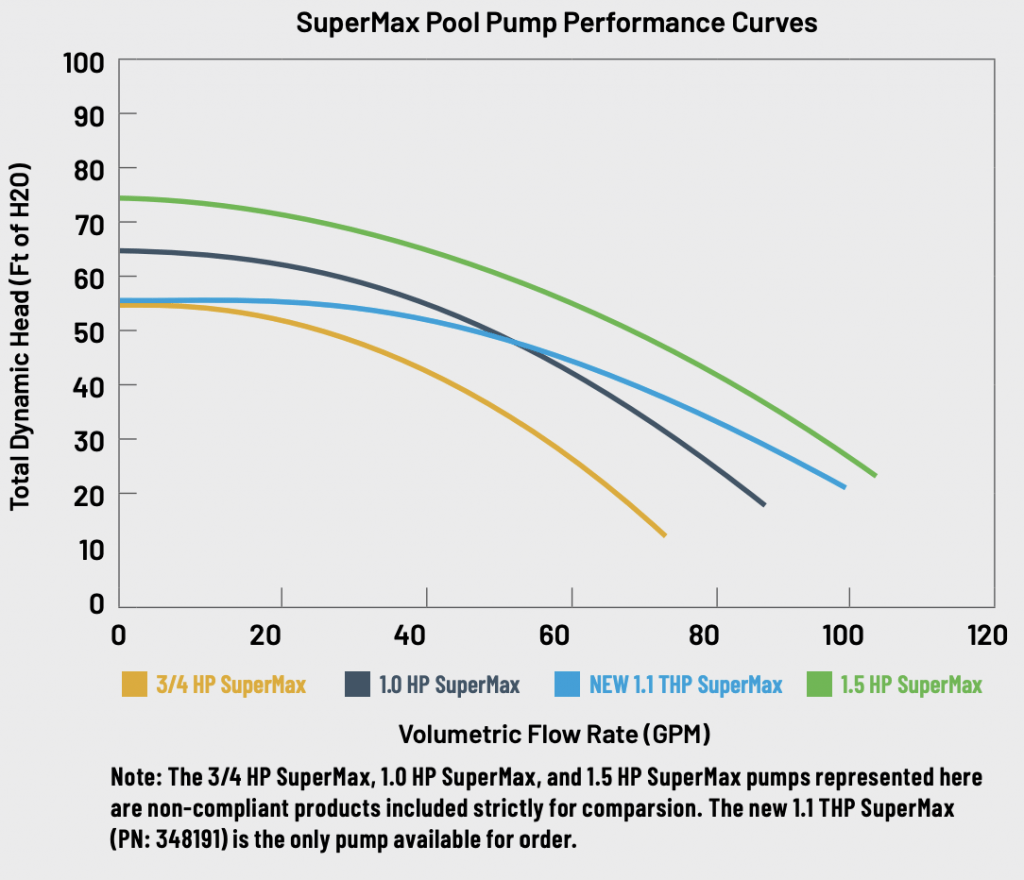

To determine your pump runtime for a single-speed pump you simply look at the chart for the specific pump you have. You determine your TDH and your GPM. Take the total gallons in your pool and divide it by the GPM to get the runtime. Let’s take a look at an example for clarification.

To determine your TDH use the following calculator. Because TDH changes with flow rate, select a flow rate that is approximate to what you would like to use for your pool. Most heaters require minimum flow of 40 GPM so if you have a heater or salt cell start with that flow rate when calculating your pump runtime.

To calculate total pool volume use the following calculator

Reference the chart above. Divide the total gallons you have calculated in your pool by the GPM you expect based on your TDH to determine total runtime. If you have a different pump than the Pentair Superflow, refer to that pump’s build sheet chart to see what TDH correlates to its respective GPM.

How to determine the RPM to set for variable speed pool pumps

For variable speed pumps the runtime is not the only factor you must consider. You also must determine what RPM or GPM flow rate you want to set, given the specific condition your dealing with. Some of the things that determine runtime might be whether or not you want to use your heater. If you have a salt cell that requires a certain GPM. In the heater example, the Pentair Mastertemp heater requires a minimum flow rate of 40 GPM. If you are trying to heat your pool you will need to run your variable speed pump at a minimum of 40 GPM to ensure the heater can stay on. If you are just looking to circulate the pool you may be able to go less depending on the size of your pool, the TDH, and the flow rate necessary to turn over your pool every 24 hours.

Swimming Pool Pump Components

Pump lid

Pump lid locking ring

Pump strainer basket

Volute

Seal plate

Diffuser

Impeller

Impeller seals

Impeller Set screw

Pump seals

Diffuser seal, lid seal, seal plate seal, drain plug orings, set screw rubber Washer

Pool pump drain plugs

Pool pump seal plate

Impeller shaft

Pool pump motor

Common pool pump maintenance items

There are quite a few common maintenance items you should be familiar with regarding your swimming pool pump. Maintaining a clean swimming pool and working equipment is essential in providing a safe, fun swimming experience for the whole family. We go over how to clean a pump basket, how to prime your pool pump, how to fix some of the most common issues with pumps, and more.

How to clean a pool pump strainer basket

- Turn off the power to the pump at the circuit breaker

- Tap gently with a rubber mallet the pump lid clamp in a counter-clockwise direction to remove the lid

- Remove the pump basket to clean out all debris. Use a small toothpick to clean out anything trapped in the pump basket.

- Put the basket back in the housing. Ensure the basket opening is facing the suction side of the plumbing. Usually, there is a notch in the bottom of the basket with a rib in the bottom of the volute to guide the basket in the correct orientation.

- Fill the pump pot and volute up to the inlet port using a garden hose.

- Clean the pump cover lid, o-ring, and sealing surface on the pump pot. Lubricate the pump lid o-ring as necessary.

- Reinstall the lid by placing it on the pot. Make sure the o-ring is seated properly and turn the pump lid clamp clockwise until the handles are horizontal.

- Slightly tapping with a rubber mallet the clamp can help ensure the lid is secured tightly.

- Turn on the power at the circuit breaker.

- Open the high pressure relief on the pool filter.

- Start the pump

- Allow the air to bleed out of the filter pressure relief until a stream of water comes out.

- Close the high pressure valve on the filter.

The pump system operates under high pressure. When any part of the circulating system (e.g. Lock Ring, Pump, Filter, Valves etc) is serviced, air can enter the system and become pressurized. Pressurized air can cause the lid to separate which can result in serious injury, death, or property damage. To avoid this potential hazard, follow the instructions in your pump operation manual or call a licensed professional.

How to prime a pool pump.

- Release air from filter via the pressure relief valve found on top of the pool filter.

- If your pool pump is below the pool water level the pump will prime itself when the suction and return lines are opened.

- If the pump is above the pool water level, disconnect power to the pump.

- Open the pump skimmer trap lid.

- Fill the pump with water.

- Clean and inspect the pump o-ring for wear and proper lubrication.

- Reinstall pump lid o-ring on lid

- Install lid back on pump trap basket by turning clockwise to tighten. TIGHTEN BY HAND ONLY, DO NOT USE WRENCHES OR OTHER TOOLS

- Pump should prime once you power up the pump. The tie it takes to prime will depend on the vertical height above the suction lift, and the horizontal length of pipe.

- If pump does not prime, refer to the troubleshooting section of this article.

Troubleshooting Swimming Pool pump problems

Low water pressure or low flow from the pump

The following are some of the most common causes of low water pressure or low flow from your pool pump.

Suction leaks

Make sure there are no air leaks from the suction piping. Make sure suctions pipe inlet is well below the water level to prevent the pump from sucking in air. Usually, this happens when your pool water level is too low and the skimmers are pulling in air with the water.

Lost prime

Make sure that the pump casing and strainer are full of water. Refer to the priming instructions in this article.

Low voltage

Check the voltage at the motor terminals and at the meter while the pump is running. If you are unfamiliar with how to safely check voltage and work with electrical, HIRE A QUALIFIED ELECTRICIAN. If the voltage is low at either the circuit breaker or pump, check for loose connections or frayed, broken, or otherwise compromised wiring.

Clogged pipe or strainer

Ensure the pump trap basket is not closed with debris. Check any pipes from the pump to the filter that has threaded disconnects for debris. Ensure the filter is clean. The pump may be trying to push too high a column of water. If this is the issue a higher-pressure pump is required.

Clogged impeller

DISCONNECT POWER TO PUMP TO PERFORM IMPELLER CHECK. IF YOU ARE UNFAMILIAR WITH HOW TO SAFELY CHECK AN IMPELLER REFER TO A QUALIFIED PERSON TO TROUBLESHOOT. To check the impeller with the pump all still connected you can reach into the pump basket with a screwdriver and reach into the impeller of the pump. Ensure the impeller turns freely. If you are unable to check the impeller or it feels like there is unwanted friction, remove the pump from the suction and return the system. Remove the 6 bolts that hold the pump strainer basket to the seal plate. Remove the volute and spin the impeller by hand. If it does not freely spin there may be a bearing or seal issue. Refer to the portion of this article to replace seals.

A clogged or dirty filter system

If you have a sand or DE filter, backwash the filter to see if it fixes the issue. If you have a cartridge filter system, clean or replace your filters to ensure adequate flow is allowed through the system. For help cleaning your cartridge filters refer to this guide.

No water coming from the pump

The cause of no water coming from the pump is usually air ingress into the system. The pump is designed to be airtight by the use of multiple seals and o-rings. To remedy this situation first, prime the pump. Check that there are no air leaks in the suction side of the piping. Ensure the pump trap basket lid is airtight, lubricated, and fitted securely. If this doesn’t fix the issue, you may have a bad impeller, bad pump seals, or bad impeller seals. Refer to their respective sections in this guide to fix them.

Reduced capacity/head

The most common cause of reduced capacity or head are;

Air pockets or leaks in suction lines

Clogged impeller

Pump strainer clogged

If you experience any of these issues, check the suction piping and valve glands on any suction gate valves. Secure the lid on the pump basket and be sure the lid gasket is in place. Check the water level to make sure skimmers are not drawing in air. Next, turn off the electrical power to the pump. Disassemble the pump following our guide in this article to check and clean any debris from the impeller. After reassembly, ensure the suction trap is clean both at the skimmer and the pump basket. This should fix the reduced capacity.

Motor thermal overload tripped

Check for required ventilation and cooling around the pump. If the temperature is able the pump’s maximum ambient temperature, turn off the pump until the air cools off. If the pump is located in a room without adequate ventilation, you may need to install air vents in the room. Check to ensure flow through the pump is not impeded. Make sure the pump basket fills all the way and does not have air.

No power at the outlet

Use a multimeter, voltage detector, or another electrical appliance that is known to work to check the power at the outlet.

Blown fuse circuit breaker

Check to see if resetting the circuit breaker or fuse fixes the issue. If the fuse or circuit breaker continues to trip, call a licensed electrician to diagnose the issue.

The pump motor burnt out due to a voltage spike or was flooded by water

Replace the motor. Use the following links to find a motor that fits your pump.

The pool pump running too slow

This is an early indication that a capacitor may be damaged. Check the line voltage. If it is less than 90% or over 106% of the rated voltage test the capacitor. If you are unfamiliar with how to check capacitor voltage, contact a licensed electrician. THE CAPACITOR CARRIES EXTRA VOLTAGE EVEN WITH THE CIRCUIT BREAKER TURNED OFF. DO NOT TOUCH THE CAPACITOR IF UNFAMILIAR WITH HOW TO SAFELY CHECK. CONTACT A LICENSED ELECTRICIAN

How can I tell if my pool pump capacitor is bad?

Show how to check for proper capacitance with a multimeter

Water leaking between the casing

Whenever water is leaking from the pump itself and not from a fitting this is due to either, casing bolts that are not tightened sufficiently (Seal plate to the motor bolts use 70-inch pounds of torque, motor sub-assembly to the strainer pot pump body use 110-inch pounds of torque), or a worn out mechanical seal which requires replacing.

How to fix pool pump leaks in the pump?

Shaft seal replacement

The shaft seal contains two parts, a rotating member and a ceramic seal. If you are leaking water out of the center of the pump, it is likely a shaft seal that has gone bad. To note, THE POLISHED AND LAPPED FACES OF THE SEAL CAN BE DAMAGED IF TOUCHED WITH BARE HANDS OR ALLOWED TO GET DIRTY. CLEAN SEALS WITH ALCOHOL PRIOR TO ASSEMBLY IF YOU BELIEVE THE SEAL WAS COMPROMISED.

Pump Disassembly

To do this repair you will need the following tools:

3/32 inch Allen head wrench

1/2 inch open end wrench

9/16 open end wrench or socket wrench

Flat blade screwdriver

#2 Phillips screwdriver

Silicone sealant

To remove the motor subassembly;

- Turn off the pump circuit breaker

- Open the filter pressure relief

- Remove the pump basket lid

- Remove the drain plugs on the pump

- Using a 9/16 inch wrench or socket remove the 6 bolts that hold the main pump body consisting of the strainer pot/volute to the rear sub-assembly

- Gently pull the two pump halves apart

- Use a 3/32 to remove the two Allen screws holding the diffuser in place

- Hold the impeller by hand to remove the smaller lock screw using a #2 Philips screwdriver. This screw is a left-handed screw so loosen it in a clockwise direction. Tighten counterclockwise.

- On the motor side of the pump, remove the shaft cap. Hold the impeller shaft from the rear of the motor using a 1/2 inch open ended wrench

- Twist the impeller counterclockwise while holding the impeller shaft to remove the impeller. Sometimes a large channel lock wrench or oil filter tool can be used if the impeller is on too tight.

- Remove the four bolts from the seal plate using a 9/16-inch wrench or socket.

- Remove the ceramic portion of the shaft seal from the impeller

- To remove the shaft seal from the seal plate, turn the plate upside down. Using a 3/4 inch PVC coupler, gently tap the seal out of the seal plate with a rubber mallet.

Seal installation

- When installing the replacement shaft seal, use a silicone sealant around the metal portion of the seal before pressing it into the seal plate. Make sure you do not get any debris or oils onto the seal itself. Ensure the seal is fully seated and allow 24 hours for the sealant to cure. The same 3/4 inch PVC coupler can be used to gently tap the new seal into place.

- Before installing the ceramic portion of the shaft seal, make sure the impeller is clean. Use a light-density soap around the rubber portion of the seal to help seal the seal into the impeller. Clean off any oils or debris from your hands with a clean cloth using alcohol.

Pump Reassembly

- Remount the seal plate to the motor by installing the bolts in an x pattern using 70 in-lbs of torque.

- Clean the motor shaft thread and the impeller insert. Screw the impeller onto the motor shaft.

- Hold the impeller shaft with a 1/2 inch open-ended wrench while hand tightening the impeller to the shaft.

- Hold the impeller in place and reinstall the impeller lock screw. Tighten to 25 in-lbs or torque. Remember to tighten this screw it is counter-clockwise.

- Remount the diffuser and install the two 3/32 Allen key screws to hold it in place.

- Install and grease a new diffuser o-ring

- Install and lubricate a new motor sub-assembly to the strainer seal.

- Grease the bolt threads. Assemble the motor subassembly to the strainer pot using the two through bolts to align. Do not tighten until all 6 bolts are in place and are finger tightened. Torque in a cross pattern until reaching 110 ft-lbs. of torque.

- Reinstall the pump to suction and return the plumbing.

- Fill the pump with water

- Reinstall the pump lid

- Turn on the pump circuit breaker

- Re-prime the system

- Ensure the filter pressure relief valve is closed after steady steam of water

How to fix cavitation.

Pump cavitation is usually caused by one of the following three things.

Debris in the pump, plumbing, or filters

Another issue that causes cavitation is fully or partially blocked plumbing. This can be in the form of a clogged filter, clogged salt cell, or other debris blocking your normal water flow.

An example we faced at Splash Doctor on one of our pools, was caused by something as small as a 2-inch o-ring. On the Hayward cartridge filters, they have a small 2-inch o-ring on the return plumbing to help hold the top manifold in place. This o-ring can get loose and in this case, was sucked out of the filter. It became lodged on the flow sensor just past the filter. This small 2-inch o-ring was causing massive cavitation in the pump. It was very difficult to find and diagnose but was just another example of how something very small can cause a perfectly working system to have major problems.

If your pump has worked correctly in the past, the first place to check for obstruction would be the pump filter basket, the filter system, and the salt cell. If those are all clear, start removing any pipes that have sensors or protruding objects to see if something has gotten stuck. We have seen this on flow sensors, temperature sensors, and more. If that does not fix the cavitation issue, we would suggest looking at the air leak section to further troubleshoot.

The pump sized incorrectly for the system

If your pump is new to your system or your pool, in general, is new, and you are experiencing cavitation in your pump, a likely cause is the pump is too powerful for your system. We helped a client diagnose cavitation issues that were caused by this. For their spa, the pool builder installed a larger-than-normal pump to try to help increase the water pressure out of each of the spa jets. While this would work if it were all sized correctly, to begin with, the plumbing coming into the pump was a 2.5-inch pipe. This pump was designed to be used with a 3-inch pipe.

The pump is a variable speed pump and initially, after installation, anytime the pump was running at 100% RPM, the pump would cavitate. The issue was there was not enough water coming into the pump to run that high. The fix for this issue was to create a limit in the programming to prevent the pump from exceeding the threshold that caused the cavitation. The pump is now limited to only 88% RPM capacity. This has fixed the cavitation issue and the spa is functioning properly.

If you have a relatively new system your issue may be the pump is just too powerful for your system. Check to see if a lower RPM or GPM setting fixes the cavitation.

Air leak

Cavitation in your swimming pool pump can also be caused by allowing air into the pump. This is usually caused by the pump lid o-ring. If you take your pump lid off and see any debris on the top of the pump basket housing or on the o-ring itself, clean everything thoroughly. Make sure the seal is lubricated properly and re-seat the pump lid on the pump.

If this doesn’t fix the cavitation, check the threaded fittings from the suction side and return side of the pump. Occasionally they can become loose, allowing air into the system. If this isn’t the problem, check for where the suction is coming from. If it is drawing from the skimmer and you have low water levels, that could be the cause of the problems as well.

If none of these items fix the cavitation problem, we have also found that a worn-out impeller, diffuser or seal other than on the pump basket to the motor can cause this issue. Check the impeller for any clogs, and debris and for freedom of movement. Check to ensure the impeller is not warped and is spinning as designed. Check for any leaks in the seals from the pump.

Pool Water Testing

Pool Water Testing